3 ·Static HSI Crusher Cedarapids Horizontal Shaft Impactors process a high tonnage of material provide excellent control over particle shape and size and accept nearly any kind of material—including recycle feed

Impact crushers can be classified into two categories vertical shaft impact crushers VSI and horizontal shaft impact crushers HSI The HSI crusher has a shaft that runs on a level plane through the crushing chamber It works by impacting the rock with hammers that are fixed on a spinning rotor It also works on the principle of

Mechanical pressure is applied using the crusher s two jaws; one is fixed while the other reciprocates There are primary and secondary types of HSI crushers Horizontal shaft impact HSI crushers are known for high reduction ratios especially when processing soft and medium hard materials

hsi crusher vs vsi crusher hsi crusher vs vsi crusher Cone Crusher Impact Crusher S Series penabrak crusher vs BVsi Crusher Australiahoteladeliacoruna a vsi impact crushers ready whenever and wherever you are there is a a vsi crusher to suit the requirements of all applications whether it is for relatively small

This equipment features Sandvik CV217 VSI impact crusher technology which produces premium shaped aggregates and sand of a consistent high quality through controlled product grading UI310 HSI impact crusher Equipment Sandvik CI721 HSI ST1263 feeder Max feed size 700 mm 28 in Capacity Up to 450 mtph 496 stph UI310 HSI

In general impact crushers both vertical shaft VSI and horizontal shaft HSI the main difference from the cone crusher is the type of crushing force The impact crusher crush by material impacting another object Jaw Crusher VS Cone Crusher 9 Key Differences Jaw crusher and cone crusher have similar crushing principle but different

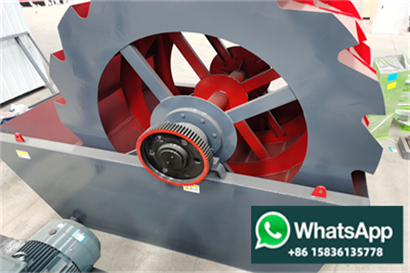

This is the main part of the HSI crusher It holds the blow bars and rotates at a high speed being driven by a pulley connected directly to the engine Blow bar / Hammers Wear parts inserted into the rotor which impact the rock to cause breakage These can be replaced when they are worn down There are three different options

In general impact crushers both vertical shaft VSI and horizontal shaft HSI the main difference from the cone crusher is the type of crushing force The impact crusher crush by material impacting another object Jaw Crusher VS Cone Crusher 9 Key Differences Jaw crusher and cone crusher have similar crushing principle but different

Engineered for the most rugged and demanding applications our extensive range of Trio® horizontal shaft impactors HSI have been developed for a variety of applications within the aggregate mining recycling and industrial minerals At Weir we offer two types of horizontal impact crushers; the APP Series and the APS Series Although both

2 ·For instance if the final size of your product only needs to be between 4 inches and 6 inches a primary jaw or impact crusher can accomplish your goals However you will likely require a much finer product and that means incorporating up to three—or even four—stations with a variety of crusher types 1 Primary Crushing

Mag Impact® VSI crusher Mag Impact® is Europe´s only true vertical impactor Magotteaux´ VSI crushers produce high quality even material at the end of the process whether you need to crush abrasive rocks such as gravel or process steel slag or limestone… They are also used for the production of railway ballast

The impact crusher for example has a higher co efficient of reduction produces crushed material with an optimal cubic shape for asphalts and concretes allows faster and simpler maintenance has a lower acquisition cost gives continuous production curves with no irregularities or breaks between sizes see Figure 1 permits bigger feed

Horizontal shaft impactors HSI offer the adaptability and capacity required to meet producer expectations With three or four bar configurations large feed opening and high performance MPR rotor Astec impact crushers are well suited for

Vertical shaft mills work on the same principal as VSI crusher with a rotor on a vertically mounted shaft using centrifugal force to throw the media against a wear plate Hammer mill Impact mills are similar in construction and principal to HSI and VSI crushers Impact mills are used to pulverize feed material by impact against a surface

Belt feeders as in VSI cannot be used for feeding due to the steep feed angle design The material fed into the crusher first reaches the core of the crushing chamber where it comes in contact with the blow bars It is very important that the incoming feed material is evenly distributed across the width of the rotor

This is the main part of the HSI crusher It holds the blow bars and rotates at a high speed being driven by a pulley connected directly to the engine Blow bar / Hammers Wear parts inserted into the rotor which impact the rock to cause breakage These can be replaced when they are worn down There are three different options

Sandvik UV320E is an integrated vertical shaft impact VSI crusher and three way split screener on a wheeled chassis Powered by electricity we have designed this unit for the production of premium shaped aggregates for the concrete and asphalt industries at a low cost per tonne UI310 HSI impact crusher Equipment Sandvik CI721 HSI

198/1 Raghavendra Mills Nadupalayam Road Pattanam Village Coimbatore 641 016 Tamil Nadu India Tel 0422 2971 6666 Ph 822 025 4888/822 024 6888/888 322 21666/822 022 1666

Weir Minerals offer two types of impact crusher suitable for primary and secondary crushing horizontal shaft impact HSI crushers and vertical shaft impact VSI crushers HSI crushers can achieve very high reduction ratios They work by accelerating the rock as it is fed from the top from where it is caught by the upward facing rotor

Quality VSI parts in various alloys ensuring a longer wear life &s; reducing your production costs Crusher Wear Parts CWP offers Vertical Shaft Impactor VSI wear parts including shoes and anvils for most makes and models VSI Quote Form II; Jaw Crusher Quote Form; HSI Quote Form; Cone Crusher Quote Form; Conveyor Belting

Our mobile impact crushers including the Sandvik QI341 & QI442 revolutionizes performance; a leading mobile impact crusher for quarrying recycling and demolition Jump to content QI341 HSI impact crusher Equipment Sandvik Prisec HSI Feed opening 992 x 670 mm 39 x 26 in mm UV210 VSI impact crusher Equipment Sandvik CV217